Inclement weather will challenge all rail freight customers at some point. Hurricanes, tornadoes, fires, and other natural dangers all pose possible hurdles throughout the year; however, one natural challenge that you can count on almost every year is winter storms, snow, and freezing temperatures.

If your organization has a facility that ships and receives railcars, consider taking measures to prepare for freezing temperatures, sleet, snow, and ice. A winter preparedness plan including snow and ice removal will be required throughout the winter season and is crucial to ensure safe and timely rail service.

2022 Winter Outlook for Rail Shipping

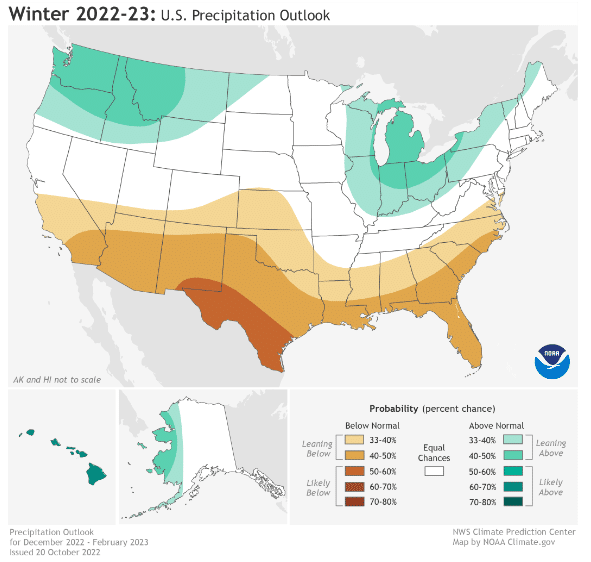

According to the National Oceanic and Atmospheric Administration, La Niña will return this winter season, driving warmer-than-average temperatures for the Southwest and along the Gulf Coast and eastern seaboard. Drier-than-average conditions are predicted across the south, and wetter-than-average conditions for areas of the Ohio Valley, Great Lakes, northern Rockies, and Pacific Northwest.

Preparing Your Rail Served Facility for Winter

In preparation for winter, you will want to perform an inspection of your physical grounds early on and take stock of supplies. Be certain that there are plenty of snow removal and deicing supplies at your facility, and that they are in working order. Any proactive measures to prevent ice build-up and slip hazards are important.

9 Tips for Preparing Your Location for Winter

Here are some helpful tips to get started:

1. Clean all switches, derails, frogs, and flangeways before freezing temperatures take place.

2. Ensure that the switch handle is clear from debris and potential snow buildup.

a. Leaves and debris can hold moisture longer, which can then freeze and prevent the switches from operating.

3. Check structures near the tracks for any drain or gutter blockage and clear those if necessary.

a. Walk the rails and check for proper drainage along there as well.

4. Railroad ties should be visible, not submerged under dirt, mud, or water.

5. Ensure that equipment can be operated through the flangeway.

a. A minimum depth of 1.5 inches is required clearance under flangeways.

6. Designate areas for snow piles removed from tracks and walkways; snow should be removed 12 feet or more away from tracks.

7. Ensure that your team has appropriate winter personal protective gear.

8. Also ensure that the facilities have proper lighting.

a. Since there is less daylight in the winter months your team, as well as the rail crews, need sufficient visibility.

9. Talk to your railroad sales rep if you have any questions or concerns about these preparation plans.

a. Many, if not all, railroads have a winter safety checklist that you can use to ensure proper preparation.

b. Review your sidetrack agreement with your rep, which may have some additional requirements.

Recovering from a Winter Storm

Throughout the winter, be aware of your weather forecasts. After any form of (or amount of) precipitation, steps will need to be taken to inspect the grounds again. This is also recommended prior to all scheduled switches. Inspect walkways, removing snow and ice as needed.

Do the same along the rails, ensuring that any derails and switches are clear and operable using brooms, shovels, and if necessary, heaters. In addition to inspecting the tracks and walkways, it’s important that the rail equipment on site is examined. Check to make sure railcars are clear of snow and ice, and that all components of the railcars are operable for the switching crews and for loading and unloading of product.

Keep in close contact with your railroad sales reps and crew members when adverse weather is expected and let them know of any storm contingency plans at your facilities.

How the Railroad Industry Prepares for Winter

Railroads take their own preventative measures and have standards for snow and removal following winter weather. Rail traffic typically rises during the winter because roadways become less reliable for trucks.

The increased rail shipping, in addition to severe weather, may lead to congestion in rail yards. To reduce the possibility of railcars bunching, it is in each railroad’s best interest to keep their rails clear as much as possible. In some cases, switch heaters or hot air blowers are used to keep rail switches clear of ice and snow.

Another method is to use glycerin based anti-freezing agents on the rails. Railroads often have a train go through during “off” hours using engines fitted with special equipment like plows, snow wings, snow blowers, and heated cabs. In addition to their own winter measures in classification yards and along corridors, the railroad crews rely on your team to ensure your facility is cared for properly. Again, your facility’s winter preparedness plan is crucial to ensuring timely switches, and the safety of your team as well as the railroad crews.

Before winter storms railroads often send out announcements regarding the potential impacts of the storm, steps they are taking, and resources used to prepare for these storms. After the storms, they will send out other communications following up on the impacts of the storm and any potential shipment delays in the affected areas.

At RSI Logistics, we also monitor the weather across North America as well as the railroad’s announcements. We keep you informed by compiling and distributing these announcements to you; you can sign up for these announcements by clicking here!

Furthermore, with our shipment monitoring services, our coordinators can identify potentially jeopardized shipments, work with the rail carriers to understand the delays, and facilitate the movement of the affected railcars when it is safe to do so.

Every year, winter storms, freezing temperatures, and snow create problems for railroads and anyone the railroads serve. That’s why it is good to prepare ahead of time and have a plan for each winter season. Your plan will involve checking your facility and supplies and having steps in place to recover if something does happen. Each railroad has similar precautions they take and similar steps in place to ensure timely winter-weather recovery to keep the rail network fluid.

If you’re struggling to do it yourself, reach out to us! We take winter safety seriously and are happy to help.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders. Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.

Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.