Bulk shipping by rail is no easy task. As shippers, whether you lease or own your railcars, they need to be shopped from time to time to complete a scheduled maintenance program or perform the annual qualifications for tank cars. Scheduling tank car qualifications can be problematic, to say the least, and can place constraints on your tank car fleet structure and shipping lanes per fleet. Here are a few tips and suggestions to make this process a little easier to deal with throughout the year. These best practices will help ensure that you will have a complete and stress-free annual shopping cycle by year’s end.

Why Complete Tank Car Qualifications Early in the Year

Fleet Visibility

The first rule of thumb as a shipper and the first reason to complete tank car qualifications early is to always have visibility of your tank car fleet to know exactly how many cars are due any given year. This part is easy, but you would be surprised how many shippers lose sight of this and scramble each year to gather how many cars are due year to year.

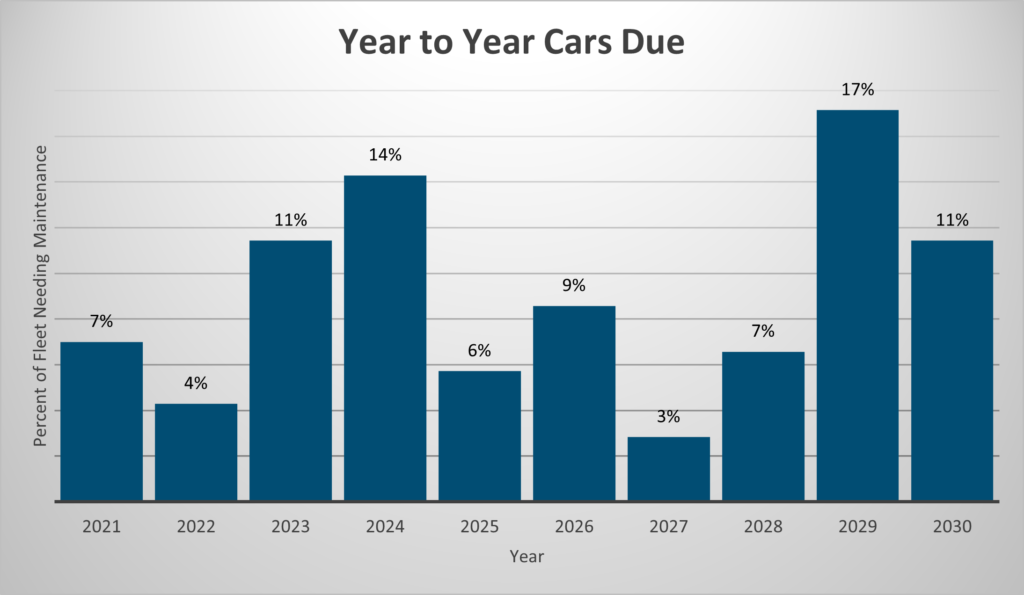

Within your given fleet, depending on your qualification cycle (10, 5, or 2½ year cycles), a percentage of your tank cars are due each year. It is good to have visibility of this for at least 10 years into the future. This helps you to understand how many cars are due for qualification year over year and gives you as a shipper an advantage to plan for heavy qualification years without disruptions to your supply chain. This visibility could help you make decisions as it relates to renewing leases or turning in excess railcars. For example, it may be worth renewing a lease for a few years if you can see that in 2 years a large portion of your fleet needs to go to the shop for qualification. RSInet provides the needed visibility to help you keep tabs on your railcar fleet and qualification dates, whether they are next year or 20 years from now.

Track Overage of Railcars

Secondly, it is usually a good idea to have an overage of railcars to accommodate those tank cars that are due for qualification, and to handle other unexpected repairs that might be needed. A good rule of thumb is to allow for 10% to 15% overage to cover these maintenance events, depending on the age and other characteristics of your tank cars.

This overage is used to cover the cars sent into shop for qualifications, which can take anywhere between 60-120 days (depending on the shop’s capacity and time of year). It also allows you as a shipper, if business is expanding or fluctuating, to have additional railcars to use if needed. Your RSI Account Manager can help you determine the ideal number of railcars based on your unique needs. Our RSInet tools also provide visibility that will help you measure how many days your railcars spend on average at any of the shops you use.

Plan to Shop

Thirdly, slow and steady wins the race in the qualifications shopping year. It is a good idea to try to plan to shop a percentage of your total cars due each month. This means as cars come out of the shop in 60 to 90 days, then as additional cars are going in, you will only be out a maximum of the percentage of cars shopped for two months.

A good example is if 60 cars are due in a year, then each month you want to send in 5 railcars. Within 3 months you will have 15 cars at the shop, but the first 5 of those cars should be coming out of the shop at the end of that 3-month period; so, you should only be out 10-15 railcars at any given time. If you as a shipper experience peak seasons and need all your railcars during that time, the shopping plan percentages will need to be adjusted during the off-peak times. Your RSI Fleet Maintenance Advisor can help you establish a good plan to ensure all your railcars are sent to the shop at the optimal time, based on your business needs and current shop capacities.

Avoid Supply Chain Disruptions

Lastly, it is not a good idea to wait until the last few months to try to shop all your railcars at once. This approach sounds good at first but is quite reactive, and you will be out the entirety of those railcars. This can create a bubble or vacuum of railcars that you are not able to use at all, causing possible supply chain disruptions. By completing your tank car qualifications early in the year, you can avoid this.

At the end of the year, if railcars are not shopped, any shipment after December 31st needs to be to shop. Many shippers fall victim to this and must end up sending too many railcars to shop at the end of the year. This approach creates bottlenecks at all shops. As shop capacities reach a maximum, this can slow down the qualification shop turn times to 120-160 days. This end of year approach means you cannot utilize the total cars due for qualification, which also means that group of cars could be out of service for 4-5 months, depending on the scenario. If additional railcars need to go to shop due to mechanical difficulties, or if your business grows and you need additional railcars, this end of year approach can disrupt your supply chain as you scramble last minute to try to pull in additional tank cars from elsewhere. Your RSI Fleet Maintenance Advisor can help you execute the qualification plans that have been established by, or with you, and report on the progress made each month, alleviating any end of year stress or surprises.

With the ‘slow and steady wins the race’ mentality, and with good visibility of each year’s qualification requirements, you can plan for heavy qualification years. By establishing a shopping plan for qualification cars, you will have fewer cars out of service and have plenty of railcars to use throughout the year, even if your business is trending upward. Contact us for more information about how our tools, services, and best practices can relieve the pressure as it relates to managing railcar qualifications.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders. Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.

Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.