Reducing logistics spending can be an uphill battle, especially in the railroad industry. Many areas are served by a small number of carriers, or even just a single carrier. Rail logistics cost reduction strategies become even more challenging with limited negotiating power. However, there are ways to negotiate and reduce rail transportation costs. As you take a closer look at your logistics, consider the following railway cost cutting strategies.

10 Rail Logistics Cost Reduction Strategies

1. Strengthen Relationships

Working with a transportation supplier that has so much market power can be a challenge. Developing a cooperative approach is important in dealing with the railroads’ sales, marketing, and operations departments. You may also be able to utilize the relationships that a 3rd party rail logistics provider may have. Strengthening these relationships is an important rail logistics cost reduction strategy, though it can take some time.

The rail operations within your facility and your fleet management play an important role in establishing your company as a preferred shipper. Plant switching difficulties, and excessive demurrage or storage charges can be a negative. It’s important to avoid incurring finance charges. When your operation runs smoothly, you’ll have more negotiating power. Careful data analysis and railcar tracking can also give you a stronger position to form more equal relationships with rail carriers. We’ll discuss data-driven rail logistics cost reduction strategies in more detail later in the post.

2. Strategic Alternatives

Approximately 70% of industry locations are served by a single carrier. If you are captive, working together with that railroad may help you grow your business, as well as theirs. Options to work with alternative carriers or modes should also be considered, especially when developing new production or distribution sites. Can your product be transloaded? Is pipeline or marine transport a possibility? Oftentimes, supply chain and logistics are not part of the up-front evaluation for new locations, but investment in these types of strategic alternatives can pay off by reducing rail transportation costs.

When we assist clients in evaluating the rail transportation for new locations we start by looking at:

- Which carriers can be accessed

- Condition and operational limitations of the tracks

- The railroad’s service plan

- In-plant track considerations including staging, loading, unloading, inspection, cleaning, and maintenance

- Potential rail origins, destinations, routing alternatives, and cost estimates from/to intracompany facilities, suppliers, and customers.

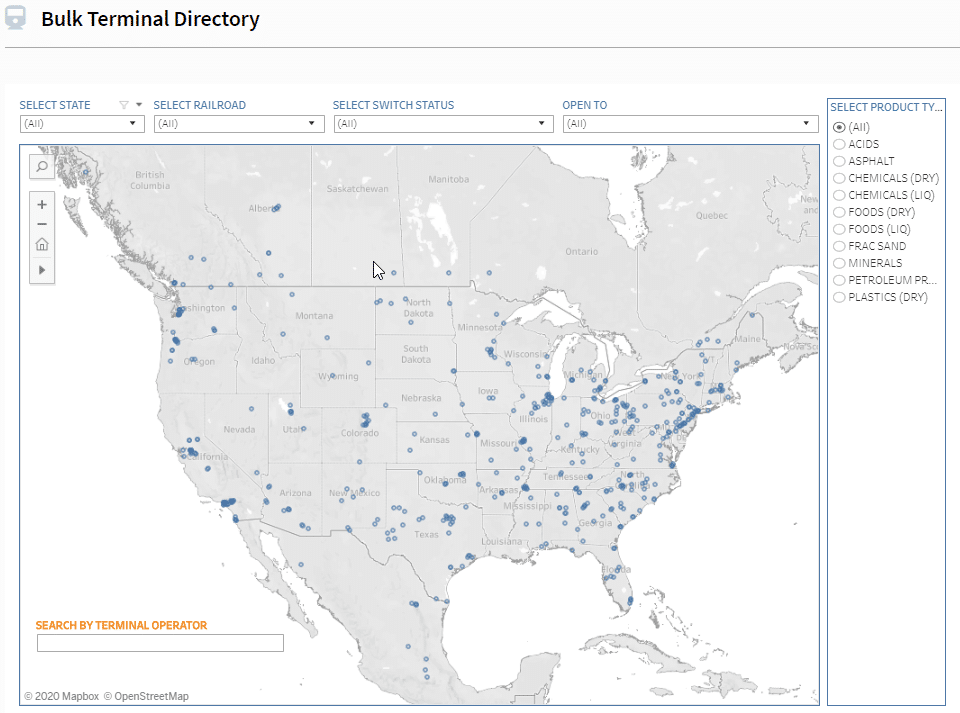

3. Rail Transloading

Transload terminals provide a way to ship by rail when a location doesn’t have direct rail services. Transloads can also be used to gain access to a competing carrier when there are no switching or interchange agreements in place. Depending on the commodity, transfer locations can range from a simple team track with space for self-transfer to a fully-staffed terminal with specialized equipment and facilities for your commodity.

4. Control Your Inbound

Rail logistics cost reduction strategies aren’t limited to negotiations with rail carriers alone. Suppliers also play an important role in the overall cost of rail transport. Suppliers focus on providing products. If you receive them on a delivered basis, the supplier may not aggressively negotiate the most competitive rate. Or, the embedded transportation rate they pass on to you may not be what they pay. When possible, take responsibility for optimizing your inbound deliveries yourself, or find a savvy third party that can do it for you. Controlling your inbound over time can help you reduce rail transportation costs in a big way.

5. Optimize Rail Equipment

Fleet assets often compose a significant portion of the transportation budget. Optimizing lease and ownership decisions, fleet sizing, and railcar configurations are an important part of reducing rail transportation costs. Make sure your railcar tracking software captures the data and provides reporting to support this process.

One of the first rail logistics cost reduction strategies to explore in regards to your rail equipment is your fleet size. Many shippers oversize their railcar fleets in an effort to avoid delaying shipments. However, an oversized fleet can easily result in empty railcars sitting outside the gate or accumulating outside customers’ facilities. This not only means excessive demurrage charges, but it also means more maintenance and monitoring costs. RSI’s Railcar Tracking & Management Software offers a Fleet Sizing Model to help you determine how many railcars you need based on actual transit times and shipping volume. With this software, you can see exactly how many railcars you need, and adjust variables, such as transit times, distances, seasonality, and maintenance, to make optimal changes.

6. Shipping in Blocks or Units

When the railroad moves groups of railcars, whether as “blocks” or “trainloads” on the same bill of lading, there are economies of scale that can translate into rail transportation cost savings for you. With multiple car shipments, the railroad switches the cars as a group rather than individually, lowering their costs and improving railcar turnaround. That equates to reduced per- diem costs for shipments in system cars. If private equipment is used, the improved car utilization could lower total lease costs when fewer railcars are required. With increased shipment sizes, the railroads’ cost savings can be in the range of 5% – 25%.

7. Evaluate Administrative Costs & Centralize Transportation Procurement

We see some shippers manage 10,000 railcar shipments per year with a rail logistics staff of 1 or 2 people, while other firms with similar volume employ as many as 8. One of the factors affecting staff size is the use of automated tools in combination with efficient processes. In client surveys, our customers report about a 25% reduction in administrative effort when converting away from a manual process.

Besides making railcar management as efficient as possible, shippers should also maximize their control and leverage by centralizing rail logistics functions. Some companies allow their plants or subsidiaries to negotiate their rail contracts independently. They may be missing some of the analytical, strategic, and relational advantages that a centralized approach can provide.

8. Stay Proactive, Analyze and Constantly Improve

Logistics departments are fast-paced environments. Throughout the day, staff are busy fielding a constant stream of requests from their business, executing shipments, tracking railcars, and resolving problems. That makes it hard to proactively identify root causes, and put long term fixes in place. This is another reason firms use a 3rd party to handle the clerical work. New insights and significant savings can often be achieved by taking a step back and analyzing current processes. Techniques including KPIs, kaizen blitz, and value stream mapping can identify significant opportunities for reducing your rail transportation costs.

9. Decrease Demurrage

Demurrage costs occur when railcars sit on the track longer than they’re supposed to. Over the past decade, demurrage costs have increased substantially, amounting to a significant portion of rail transportation costs. Analyzing, understanding and decreasing demurrage is an important rail logistics cost reduction strategy.

Demurrage costs have increased for all but one major rail carrier, while volume remained mostly steady, or decreased. These costs have increased so much, it caused the Surface Transportation Board to schedule a hearing. Yet, many shippers don’t take a close look at their demurrage charges. Many who do find that their demurrage costs have increased notably, while other operations haven’t changed.

There are several ways to decrease demurrage charges. Consider the following:

- Reporting tools: Accurate data can tell you if your demurrage charges are in line, or not. This can also give you a way forward. Use trace reports to track charges, delays, arrivals, transit times, railcar issue logs, and more.

- Optimize your fleet: As previously mentioned, too many railcars sitting on the track results in excessive demurrage charges. Take a closer look at your fleet and make cuts where necessary.

- Report undue charges: If a delay was caused by the rail carrier’s mistake, you should not be charged for it. However, these costs are often transferred to the shipper without a second glance. Take a look at these charges, and use your movement data to see if they make sense or not.

- Review instructions: Are your railcars designated as open or closed gate, spot-on-arrival, or keep me full? Knowing these designations and how rail carriers treat cars with each designation can help you move the cars more efficiently.

10. Utilize Data Strategically

Forging strong relationships with your rail carrier is one of the best rail logistics cost reduction strategies. However, strong relationships are difficult to create if the two parties are unequal. If you have little negotiating power against a single rail carrier, you’ll end up in a subordinate position and, likely, paying higher rail transit costs. Data and visibility can help to equalize this relationship and give you more negotiating power.

Consider the following data sets and how they can be used in railway cost cutting negotiations. Rail Impact can give you access to these data sets and many others to help your rail logistics cost cutting and negotiations.

- Data on rail rates in your industry, and where your rates rank

- Rate and volume trends in your industry and for your shipping materials

- Railroads’ operating and fuel surcharge miles between stations

- Alternative routing options and transload facilities

- Rail carriers available along your route, or alternative, comparable routes

First, take a closer look at your rail shipping costs. If your costs seem out of line, use these rail logistics cost reduction strategies to reduce your rates. Get the right data, streamline your operations, strengthen your negotiations, and keep your operations on track into the future.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders. Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.

Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.