If you own or lease your railcars, it is important to understand how many railcars you need. Having a grasp of your necessary fleet size helps to ensure that your product is delivered to your customers on time. Although many rail shippers may consider increasing the number of railcars in their fleet(s) to ensure that they always have enough railcars to cover rail shipping needs, in reality this often ends up exaggerating the required amount. Having too many railcars in your fleet can create just as many challenges as not having enough.

Consider the scenario that you have too many railcars in your fleet and what those railcars do when they are not in use:

- Is your plant full of empty railcars?

- Do you have empty railcars stacked up outside of your gate waiting for free space in your plant?

- Do you have service issues driven by congestion in local yards?

- Do you store empty railcars at off-site locations?

These excess cars are costing you money!

Shipping and Fleet Sizing

You may think, what about shipping them to customers early? While this will remove congestion from your plant and serving yard, it may create problems for your customer’s locations. Many of your customers likely order material based on known rail transit times. Shipping railcars early results in congestion, service issues, and demurrage at your customer’s locations. This “solution” could quickly lead to strained relations with your valued customers!

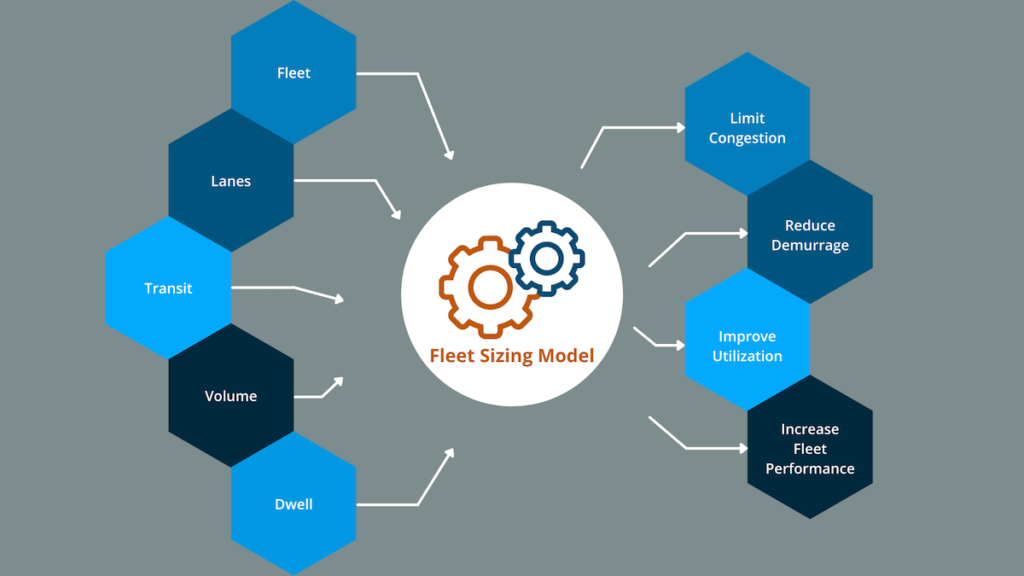

Savvy shippers seek to understand their demand, transit times, and railcar needs to accurately size their fleet. However, the biggest question for many shippers is how do I correctly size my fleet? Our Railcar Tracking & Management Software offers a Fleet Sizing Model that was developed to help rail shippers determine how many railcars they need based on actual rail data, such as transit times and shipping volume. Our Fleet Sizing Model also offers the ability to include buffers for seasonality and railcar maintenance requirements.

We call it a Fleet Sizing Model because it is an interactive tool that allows you to adjust variables to determine how they affect the number of railcars you need. Adjustable variables include days at origin, days in transit, shipment volume, and more!

Fleet Sizing Considerations

Consider a scenario where you anticipate a significant growth in business. Do you know where to start planning? Or how to account for the impact an increase in rail shipments will have on your railcar fleet? With our Fleet Sizing Model, you can adjust the shipment volume in each of those respective shipping lanes to understand how many railcars you should dedicate to that business.

Do you have an entirely new customer and are unsure how many railcars it will require to accommodate the new business? Our Fleet Sizing Model allows you to enter anticipated shipment volume, transit times, and customer throughput. Using these variables, the Fleet Sizing Model will determine the appropriate number of railcars to support your new venture.

What about plant throughput that is longer than the ideal, or required, throughput time? If your fleet currently has too many railcars, the number of days that each railcar sits at your plant is potentially exaggerated – because the cars must sit somewhere. In this case your actual transit data might reflect that on average, it takes your plant 10 days to throughput a car, but you know that your plant can do it in 4 days. The Fleet Sizing model allows you to adjust this variable to understand the impact to the number of railcars required.

The same concept applies on the customer side. If your customer(s) hold railcars for extended periods of time, you can push them to release the railcars back to you sooner. To determine the impact customer hold days has on your fleet size, you can also adjust this variable to perform a “what if analysis.” If your actual transit data show that the customer holds your car for an average of 20 days, you can adjust the variable to 15 days to understand the impact to the number of railcars required.

Fleet Sizing Tools

Beyond our Fleet Sizing Model, additional Transit Summary, Transit Detail, Dwell and Shipment Volume Reports are extremely useful in determining an appropriate fleet size for your organization.

Regardless of private or system railcars, shipment visibility in our Railcar Tracking & Management Software helps you easily measure transit times and required lead times. Using the appropriate lead time helps customers order with the appropriate date and shippers fulfill the shipment on the appropriate date. This contributes to a better relationship between shippers and customers while also reducing demurrage, service issues, excessive equipment lease costs and more!

In the era of Precision Scheduled Railroading, strict demurrage charges, and increases in rail freight, it is key to control costs. Implementing a strategy to accurately size your railcar fleet is the first step in the right direction. Contact us if you would like to discuss how we may be able to help.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders.

Automated exception reporting of the railcar tracking data makes it easy to identify and troubleshoot jeopardized shipments, thereby enabling you to provide better service to your stakeholders. Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.

Receive notification of pending rate expirations. Tariff changes and fuel surcharges can be automatically updated.